HFIX (KS C 3341)01The first slip agent used in domestic water Cross-Linked methodThe slip agent which minimizes the surface friction coefficient is added to the insulator compound, so that it can be smoothly inserted in the pre-insertion work. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

02

Submerged water immersion testProducts Underwater immersion Long term reliability TEST / Initial submersion Date 2014. 02. 01 ~ Present 2017. 05. 30 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

03

Flammability testNot exceeding 10Cm at the point of carbonization after flame burning. Eco-friendly flame-retardant insulated wire that does not generate toxic gas in case of fire. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

04

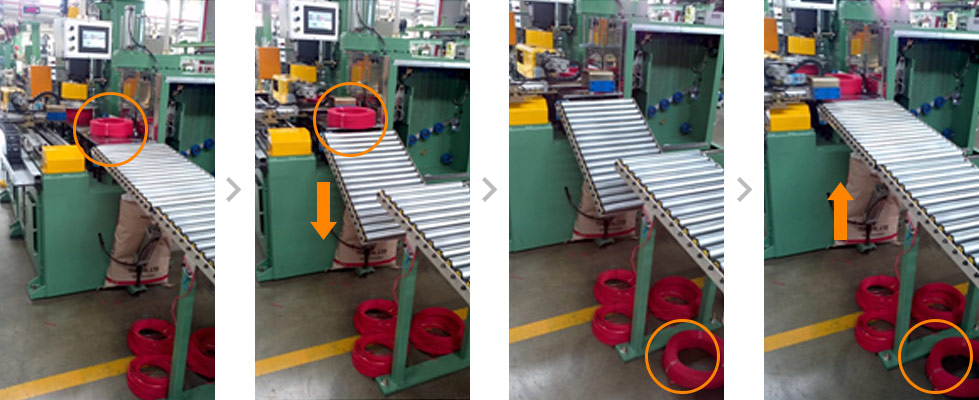

Quality management differentiationHFIX process automation line introduction

* Detector, outer diameter meter, spark tester are linked each other, bad product alarm sensor operated products, automatic sorting on conveyor

HFIX schemeIndoor wiring conductor Low toxicity flame retardant polyolefin insulated wire with maximum use temperature of 90 ℃

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flagship Product

Seoil Electric Wire Co.,LTD Self-reference Test (Feb. 2014 ~)

| Division | Photo | Room temperature insulation resistance reference test (unit: ㏁, km) | |

|---|---|---|---|

| Initial measurement value | Current measurement value | ||

| No electric current |  |

2090 | 1920 |

| Applying 220V electric current |

|

1565 | 1395 |

| Cement addition |  |

1570 | 1485 |

Precautions

Precautions