01

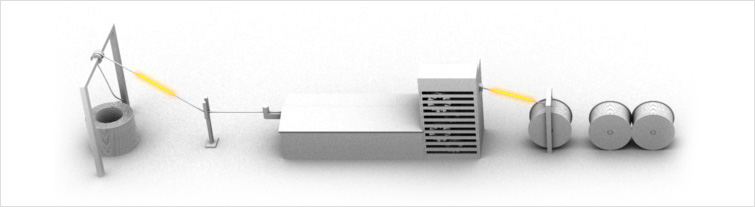

Drawing |

In the wire factory, 8mm (types: YCR and JCR) wire conductor are padded through the first drawing machine (13 dies) and the second drawing machine(17 dire) to prudence minimum 0.45mm wires. |

|---|---|

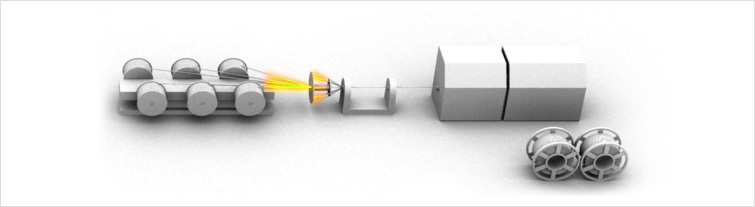

02

Stranding (round copper strands) |

The wires (conductors) produced from the drawing process are twisted and combined like a straw rope in 7 threads (center 1, cithers 6). |

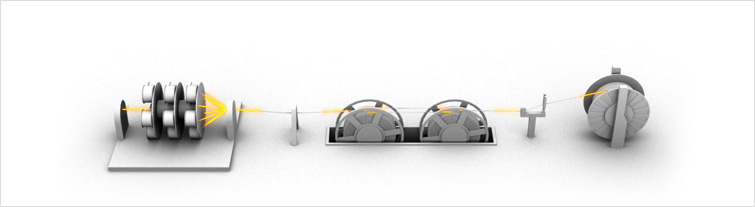

03

Insulation |

Ist Covering (Insulator) Point the insulators covering the round strands become insulated wires if the approval organization, approval number, item, size, quantity, and manufacturer are printed on the insulator, when the coated insulators are moved to the combining process, they are named as cores, and numbers (Arabic numerals) are printed on the insulators by color. |

04

Combining (twisting and combining of cores) |

The insulated cores are combined and twisted together with inclusions to fill grooves, and they are horizontally wound with tapes to prevent the cores and inclusions from getting loose. |

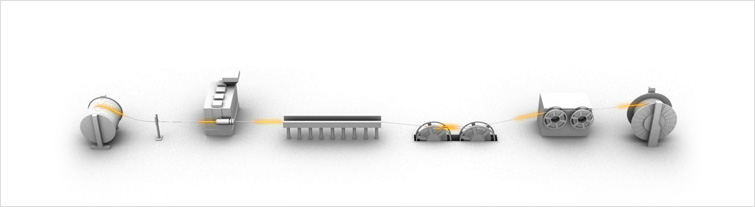

05

Covering (sheath or cover) |

The core combined products are covered for the second time to protect them from external high of low temperatures and impacts. product information (printing details) are printed through the Z-print, Then the products are aligned and wound to wooden drums in this last process of wire production. Printing details Approval organization mark, name/ approval number/ rated voltage/ item and size/ manufacturer/ production date/ length |

Product of application

Show